Let's talk needles (because we've already covered pins). People, your needle is the lynchpin (ha! see what I did there?) to good sewing. Different fabrics require different needles, and even within those categories, there are subcategories. But before we drill down, let's look at the anatomy of a needle.

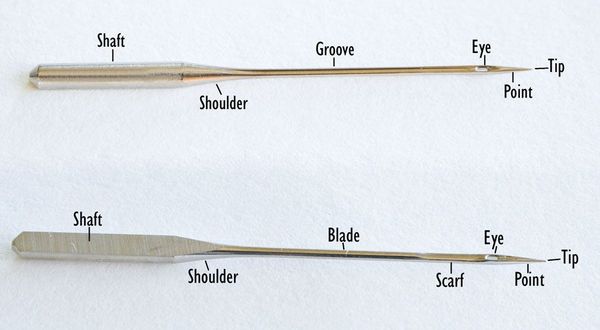

Here's your typical sewing needle. It has a round side and a flat side, and narrows to a shoulder (which usually has a colored collar indicating the type and size). The long part is called the blade on the flat side and grove on the round side (this is where the thread lies as the needle penetrates the fabric), and then there's the scarf (the flat bit right before the eye that is critical to the forming of the lock stitch), the eye (which accepts the thread), the point and tip.

Now let's take that deep dive.

Needles, and let's be honest, OLD or WRONG needles can be the source of so much frustration when sewing. I'm no longer surprised when a student brings her machine to class and declares: "I've never changed my needle, but my sewing machine just doesn't work right." The first habit you should get into is CHANGE YOUR NEEDLE WITH EVERY PROJECT. Personally, I sew several hours each day, so I change my needle weekly. At the very least, change your needle every 8-12 hours of sewing.

And choose the right needle. Machines typically come outfitted with a "universal" needle, and those needles are perfectly fine, but as you become more skilled as a sewist, you'll start to recognize sloppy stitches or a struggle to get through fabric--that's the needle folks!

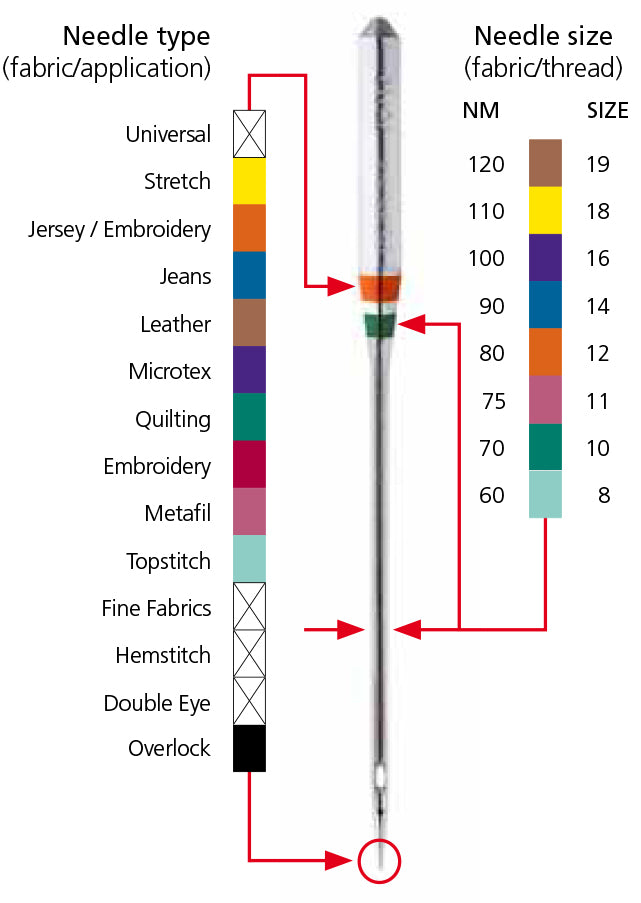

You'll notice when you buy a pack of needles there are TONS of numbers and bands of colors on them. The numbers refer to the different sizing standards (European/North American), and the colors refer to both the needle type and needle size.

So what do all those colors stand for? If your needle has a top color band, that indicates the type of application or fabric you can use. The 2nd color band indicates the needle size, which is important for determining what kind of needle to use with different fabrics and threads.

For example, I sew A LOT of jeans. Therefore, my jeans needles should have a blue band on top and purple band on bottom. For piecing a quilt block, I might want a universal needle (no top band) and if I'm using typical quilting cotton, then a teal (70) or orange (80) bottom band. But when I'm quilting, I'll go with a darker teal top band and an orange (80) or royal blue (90) bottom band.

Here's a short video where I talk about matching needles to fabrics.

Now that you're armed with knowledge--go visit your LQS and get yourself some needles! You won't be sorry!

Stay in touch and Show us what you've made:

Instagram: @sewingbysarahstore

Facebook VIP Group: https://www.facebook.com/groups/sbsvip

Download your FREE Presser Foot Quick Guide Here:

Leave a comment (all fields required)